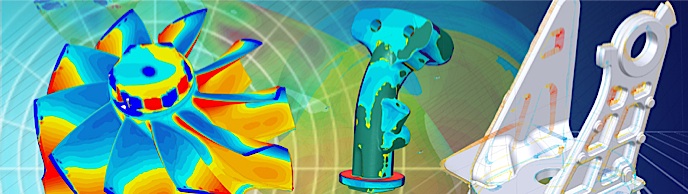

3D scanning can be an effective tool for first article inspection. It is relatively fast, produces accurate results, and can be more cost-effective than other solutions. However, 3D scanning does not work for every first article inspection application. For example, if the part includes internal features or surface finishes that are not compatible with optical inspection tools, a different approach might make more sense.

If you have determined that 3D scanning is the right method for your application, following a set of key best practices will help ensure that you achieve the highest quality results.

First Article Inspection Best Practices

- Accuracy - Although accuracy varies depending on the application, a good guideline is for 3D scanning to be 4 to 10 times more accurate than the tolerances for the part. If you're not sure what to specify, work with your provider to determine the range that will produce the results you desire.

- Object condition - Make sure that the part you are scanning is clean and free from any surface debris. This is especially important for non-contact 3D scanning because any particles left on the object will be included in the point cloud obtained during the scanning process.

- Speed - First article inspection typically depends on speed. Most manufacturers want to get confirmation that a part meets specifications as soon as possible so they can start or continue production or take corrective action, if necessary. Working with a 3D scanning lab before you provide the part for inspection can improve the turnaround time for results. Your provider can do advance work such as pre-programming the point cloud inspection software (such as Rapidform XOV or Geomagic Verify) to make the scanning process more efficient.

- Quality - When it comes to first article inspection, results are extremely important. A mistake can cost manufacturers time and money. Although speed is an important factor to consider, it should not come at the expense of quality.

- Experience - 3D scanning is still a relatively new dimensional inspection technology, and not every lab has expertise with the equipment and software. Make sure you work with a certified provider that has a track record of success with 3D scanning.

Q-PLUS offers 3D scanning services for a broad range of industries and applications, including first article inspection. We'll work with you throughout the entire process to ensure that you get the fastest, best results. Request a quote today to learn more about our 3D scanning services.

What are the challenges you experience with performing first article inspections?