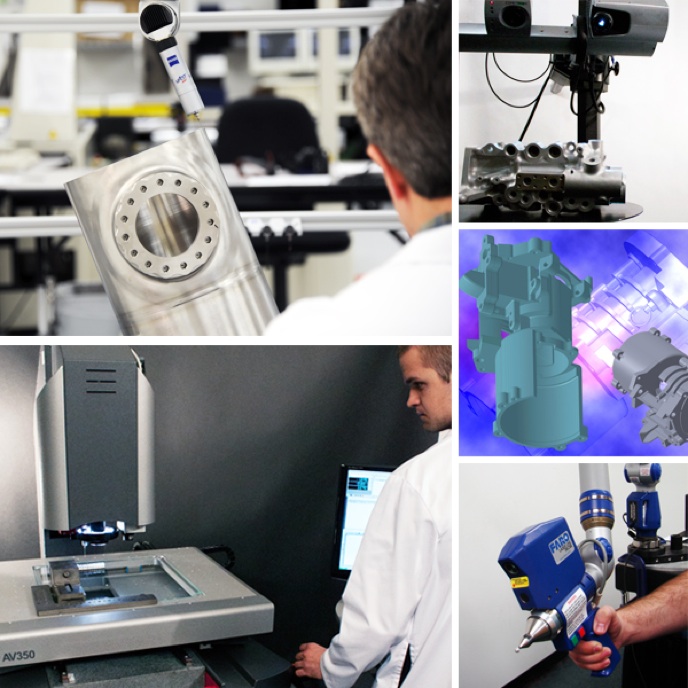

3D scanning can be used for multiple reasons, including first article inspection, reverse engineering, and other types of measurement applications. The purpose of 3D scanning is to collect data points to create a digital representation of the object. These data points can be gathered using lasers, white light, contact sensors, and other methods depending on the characteristics of the object being measured.

Although the objective behind the technologies are similar (obtaining measurement data), not all 3D scanning equipment is the same. For example, some equipment gathers data by coming into contact with the object, while others use non-contact optical technology to collect measurements.

Four Factors for Selecting 3D Scanning Equipment

If you plan to purchase 3D scanning equipment, you want to be sure of your choice. Consider the following factors as you reach a decision about what to buy:- Object characteristics - 3D scanning equipment can be used to collect measurement data for objects of almost all shapes and sizes. However, the type of equipment you select depends on the surface characteristics of the object, whether it has internal geometry, its size, and other factors.

- Speed - How fast do you need results? Some devices provide faster results than others; however, speed can also impact quality and accuracy, so look at the big picture when you consider what equipment to buy.

- Accuracy - This factor is extremely important in many industries. Do you need NIST traceability or an accuracy statement? Make sure that the equipment you buy can meet the accuracy requirements for your applications.

- Cost - The cost of 3D scanning equipment varies, even within the same type and class of technology. Although equipment price is an important consideration, it should not be the only one. If the equipment you buy can't produce the results you need, your money will have been wasted.

Purchasing 3D scanning equipment is not your only option; you can also work with a qualified lab to outsource measurement services. This can be a more cost-effective solution if you don't often need 3D scanning or will be measuring multiple types of objects.

Whether you decide to buy equipment or outsource services, Q-PLUS Labs is here to help. We are a certified reseller for multiple manufacturers, and we provide 3D scanning, reverse engineering, and dimensional inspection services to all types of industries. Request a quote today to get started.

Do you want to embrace this modern method of measuring but don't know where to start?