In manufacturing industries where the difference in a decimal point may determine whether a 21st century elite battleship sinks or floats, quality is as integral as the bolts that bind that vessel together. Finding a dimensional inspection lab that can not only proficiently provide a variety of services, but also do so reliably and consistently can prove to be a daunting task if you are not equipped with the right criteria. Although each manufacturer has different dimensional inspection priorities, there are a few key factors to consider in finding out if a dimensional inspection provider will help you operate more efficiently and possibly save you both time and cost in the process.

Key qualities to consider when selecting a dimensional inspection service provider are:

- Industry Expertise - Almost any engineer can perform basic dimensional inspection with a little training. In fact, there are many reasons engineers benefit from learning more about metrology. However, dimensional inspection in the context of the manufacturing world is an entirely different story. You need a partner that understands industry-specific requirements, manufacturing methods, and can interpret engineering drawings properly. If they are already familiar with the factors involved in measuring your application, the expertise of your dimensional service provider can help in maintaining a tight production schedule. An experienced provider will be able to not only provide you with a detailed measurement report, but also advice on how the results may directly affect your application.

- Modern Equipment - Although the field of dimensional measurement has existed since even before the first standardized measuring tools were created, the technology is constantly evolving. A facility that doesn't stay on the cutting edge of 3D scanning technology and all the other measurement technologies and methods may not be able to provide the most efficient and accurate services. Look for a lab that regularly updates its equipment inventory so that you can get the best service now and in the future.

- Attention to Detail - Even the smallest cut corner can have a major impact on a manufacturing process, which is why working with a provider that is as committed to the little details as you are is so important. As the world of manufacturing in progressing more into the nano realm than ever before, it is important to consider a provider who can offer both accuracy and insight into the needs for dimensional inspection across the size scale for manufacturing.

- Broad Capabilities - As the world of manufacturing is progressing more into the nano realm than ever before, it is important to consider a provider who can offer both accuracy and insight into the needs for dimensional inspection across the entire size scale for manufacturing.

- ISO 17025 Accreditation - An ISO 17025-accredited lab must meet certain quality standards so that you can be confident that your project will get the attention it deserves. ISO 17025 accreditation meets and exceeds the requirements of ISO 9001. Although many dimensional measurement facilities achieve ISO 9001 registration, not as many make the extra effort for ISO 17025 accreditation. The advantages of using an ISO 17025 accredited lab are numerous. For example, each measurement machine in a scope of accreditation must be subject to rigorous measurement uncertainty studies and round-robin testing in addition to accredited calibration.

- Technological Aptitude - Metrology technology and equipment are constantly evolving, which means there are always new ways to do the job better, faster, or in a more affordable manner. Look for a partner that has competence in all the modern methods of dimensional inspection using the latest technology so you can reap the benefits.

- Forward Thinking - The manufacturing process requires many steps, and to get it right the first time, you must have foresight and think strategically. Look for a provider that is invested in the whole process, not just the measurement tasks you require. An experienced dimensional metrology provider should be able to consider all factors when it comes to measuring your application, and provide you with a coherent plan that includes aspects such as your budget, your team's experience, and overall quality goals.

- Qualified Employees - Dimensional measurement requires both training and experience. Make sure your provider is staffed with technicians who have the level of expertise required for your application.

- Prompt Service - Some dimensional measurement services can't happen overnight, but you should be able to communicate with your provider as often as necessary. Look for a lab that responds quickly to your inquiries and has the flexibility and capacity to provide rush services if you need them.

Poor testing procedures and inadequate equipment can cost you a lot of time and money, both in the short-term and in the long-term. In order to meet minimum quality standards you need the right equipment and a trained staff that knows how to use it.

Q-PLUS Labs has been a leading dimensional measurement laboratory since 1987; providing one place for precision measurement solutions. As a lab registered to ISO 9001 and accredited to ISO 17025, you can be certain that you will get the right dimensional measurements every time, on time. Contact us today for an assessment.

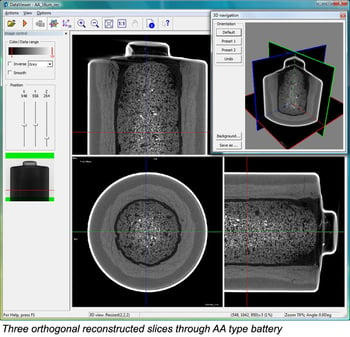

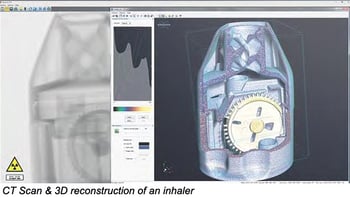

CT scanning does not require any external forces such as pressure or stress to be applied on the part being scanned. Instead, it uses X-ray technology for internal inspection. This method uses an X-ray source to transmit a beam or beams through the part, causing thousands of 2D X-ray images to be captured by the detector panel. Unlike 3D scanning which uses structured light or laser to capture a point cloud, these multiple X-ray images combine to form voxel data. A voxel is a volume element in the form of a pixel or point in 3D space. Using software, these images are then reconstructed slice by slice into a 3D model which can be analyzed further. For dimensional measurement purposes, the voxel data is typically converted into a precise point cloud using very specialized purpose-specific software. The point cloud can then be post-processed into inspection results or, for reverse engineering, a 3D CAD model.

CT scanning does not require any external forces such as pressure or stress to be applied on the part being scanned. Instead, it uses X-ray technology for internal inspection. This method uses an X-ray source to transmit a beam or beams through the part, causing thousands of 2D X-ray images to be captured by the detector panel. Unlike 3D scanning which uses structured light or laser to capture a point cloud, these multiple X-ray images combine to form voxel data. A voxel is a volume element in the form of a pixel or point in 3D space. Using software, these images are then reconstructed slice by slice into a 3D model which can be analyzed further. For dimensional measurement purposes, the voxel data is typically converted into a precise point cloud using very specialized purpose-specific software. The point cloud can then be post-processed into inspection results or, for reverse engineering, a 3D CAD model. While CT scanning produces highly accurate results without physical damage to the part, it is not an ideal testing method for every type of part. Parts that are very large, or are made of high density materials, or have very flat dimensions provide a challenge when scanned using this method.

While CT scanning produces highly accurate results without physical damage to the part, it is not an ideal testing method for every type of part. Parts that are very large, or are made of high density materials, or have very flat dimensions provide a challenge when scanned using this method.

the most basic systems use hard probes and XYZ read-outs, while the most complex employ fully automated continuous contact probing. For a system like a bridge CMM which uses this set of axes, each axis is used to indicate the system's position or location in space. The probe head determines the values on the Z-axis by moving up and down the system's bridge. The system's Y-axis determines its values by moving over the entire CMM's base. The values for the X-axis are determined by moving back and forth across the bridge.

the most basic systems use hard probes and XYZ read-outs, while the most complex employ fully automated continuous contact probing. For a system like a bridge CMM which uses this set of axes, each axis is used to indicate the system's position or location in space. The probe head determines the values on the Z-axis by moving up and down the system's bridge. The system's Y-axis determines its values by moving over the entire CMM's base. The values for the X-axis are determined by moving back and forth across the bridge.