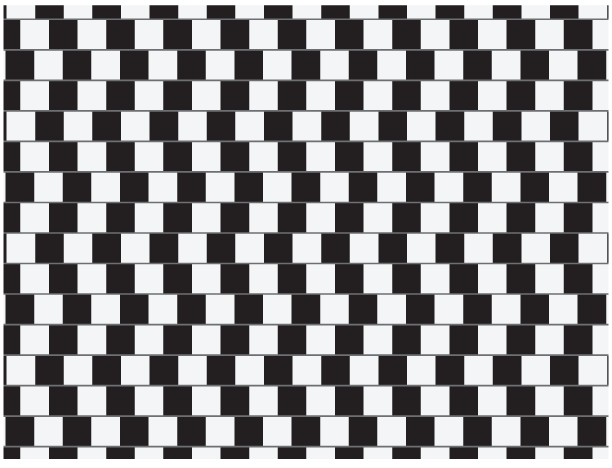

Optical illusion: parallel lines made from black and white pillows

Optical illusion: parallel lines made from black and white pillowsVisual inspection is perhaps the original method, and it is still often the first line of defense in inspection and verification processes. The eye is a powerful inspection tool mainly because it is connected to a human brain that possesses information and skills that machines do not. However, the eye can be tricked, so knowing its limitations is important.

The Strengths of Visual Inspection

Almost all manufacturing applications should include visual inspection at some stage of the process for these primary reasons:- Save money - If there is an obvious flaw that can be seen by the naked eye, there is no need to take the time and resources to continue the inspection process.

- The human element - Dimensional inspection evaluates just that: the dimensions. But what if the object produced is a mirror image of the intended result? This could be overlooked in an open setup or a non-model-based CMM inspection because the dimensions might exactly match the specifications. However, a visual inspection to compare the final product with the engineering drawings would quickly show the mistake.

- Evaluate workmanship - Certain types of dimensional inspection equipment measure the edges of an object but not the surfaces, or vice versa. Take the example of a cube. Your CMM might confirm that the surfaces of the cube are the correct dimensions, but it might not detect a large gash on one of the edges. Visually inspecting parts can help ensure that all of the specifications are met, not just the ones the equipment can see.

The Weaknesses of Visual Inspection

Although the human eye is a sophisticated tool, it can also be easily tricked. Consider some of these weaknesses associated with visual inspection:- Unreliability - Browse through these optical illusions to get a sense of just how unreliable the human eye can be. This does not mean that visual inspections are always unreliable, but that they shouldn't be your only method of inspection.

- Imprecision - The human eye is not capable of making precise measurements, especially on a very small scale. Even when comparing two similar objects, the eye might not notice that one is slightly smaller or larger than the other. This concept also applies to characteristics such as surface roughness, size, and any other factor that needs to be measured.

Clearly, visual inspection comes with advantages and disadvantages but the value of it should never be quickly counted out. The best approach to effective dimensional inspection is one that includes multiple methods. Q-PLUS Labs is here to help you decide which dimensional inspection approach is right for your application. Contact us today to schedule a consultation.