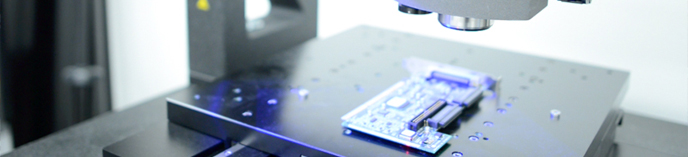

Dimensional analysis involves the comparison of a manufactured part or component to the specifications defined by engineering drawings, digital files and 3D CAD models, or a master tool or part. Historically, the scale of measurement capability has ranged from very large (airplane wings and automobile contours) to the micro level (printed circuit boards and micro electronics). However, as technology has evolved to include the development of manufacturing at the nano scale, dimensional analysis has needed to maintain the same pace.

Manufacturers and researchers have long been able to design parts with features or surface characteristics that can be specified at the nano level, but until recently, the technology did not exist to measure and validate at the same scale. The development of new equipment that uses a combination of different types of advanced technology to achieve greater accuracy at the nano scale is opening new doors for manufacturers to create the innovative products that they previously could not verify.

Nano Measurement in Dimensional Analysis

Some of the applications in which nano measurement can be applied in dimensional analysis include:

- Precision valves

- Medical blades

- Orthodontics

- Artificial joints

- Inkjet cartridges

- Printing and paper manufacturing

These are just a few examples of the many industries and applications that regularly use nano measurement to verify specifications, perform quality control tests, and reverse engineer parts.

Like other types of dimensional inspection, nano measurement can be performed to collect a broad range of data, including:

- Surface roughness

- Form

- Flatness

- Roundness

- Sharpness

- Step height

- Wear

- Texture

- Defects

Results can be delivered in two or three dimensions, including full CAD renderings. Both contact and non-contact methods can be used, so almost any type of object can be effectively measured, including reflective surfaces.

In order to stay on the cutting edge of dimensional inspection, Q-PLUS Labs has kept pace with new nano measurement technologies. This means that we use the most advanced equipment available to provide accurate results with the highest resolution. If you are looking for outsourced nano measurement services, Q-PLUS Labs is an industry leader with a wide array of instruments and skilled professionals with expertise across many fields. Contact us today to learn more about our services.