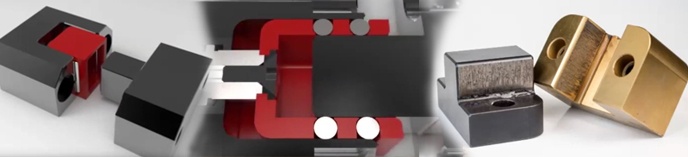

Extreme Components, LP is known for designing and creating cost-saving, effective alignment/positioning devices for the Injection Mold Industry that are durable, reliable, and high precision. Their molding alignment locks are manufactured using dynamic alignment technology or DAT, which is a revolutionary method for self-aligning locks that involves minimal friction and wear, even at high speeds. Using Q-PLUS Labs’ nano measurement expertise, Extreme Components, LP wanted to use the surface finish analysis results to find out precisely how well their DAT locks held up against the wear of daily use versus the traditional friction-fit locks.

Introduction

Extreme Components, LP's unique product was designed using DAT which consists of rollers constrained in a cage, and moving in a prescribed manner due to the kinematic relationship between the rollers. The tongue is moved relative to the housing without direct mechanical contact between the tongue and the housing. Because there is very minimal friction between parts, the process decreases the amount of wear that would normally be experienced using methods such as those used with traditional friction-fit locks.

Our Process

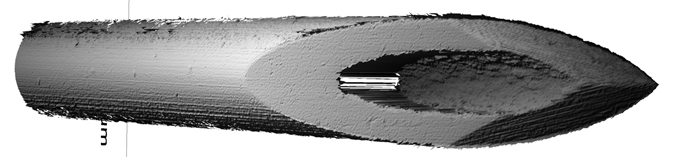

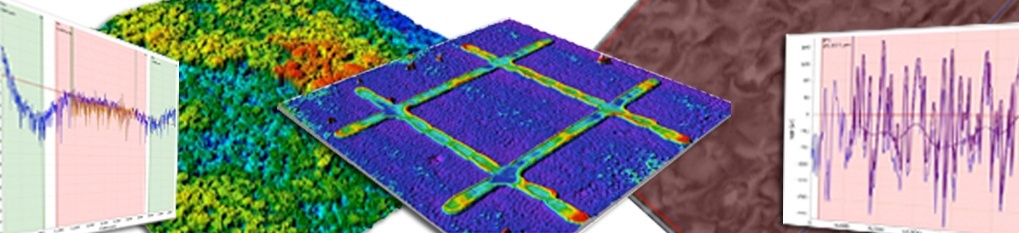

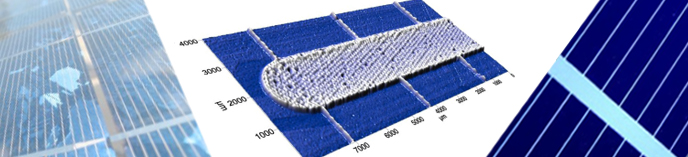

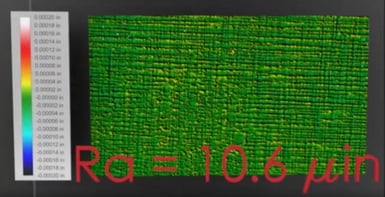

To analyze the exact amount of wear, Q-PLUS Labs performed a surface roughness analysis to confirm the wear on the unused surface of a traditional friction-fit lock versus the wear experienced by Extreme Components LP’s DAT locks after multiple uses. This was accomplished using white light profilometry from CyberTechnologies’ CT 300. The subsequent data from the unused surface of a friction-fit lock revealed an average roughness of 10.6 micro inches. There was major deviation from the level surface while the actual tongue contact surface was too rough to measure using conventional high precision instruments due to galling, or wear caused by adhesion between sliding surfaces, which could be observed from visual inspection.

To analyze the exact amount of wear, Q-PLUS Labs performed a surface roughness analysis to confirm the wear on the unused surface of a traditional friction-fit lock versus the wear experienced by Extreme Components LP’s DAT locks after multiple uses. This was accomplished using white light profilometry from CyberTechnologies’ CT 300. The subsequent data from the unused surface of a friction-fit lock revealed an average roughness of 10.6 micro inches. There was major deviation from the level surface while the actual tongue contact surface was too rough to measure using conventional high precision instruments due to galling, or wear caused by adhesion between sliding surfaces, which could be observed from visual inspection.

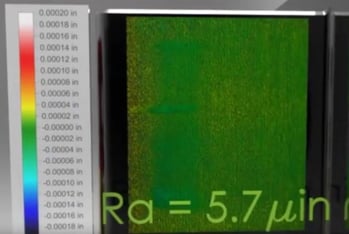

In comparison to the friction-fit lock, Extreme Components’ DAT lock that had been used by a multinational medical device manufacturer for 4 years of near continuous service, cycling every seven seconds with a 2,300 pound load yielding more than 10 million cycles, was measured to have a surface roughness of only 5.7 micro inches. The data of the surface map displays better uniformity than the friction-fit lock, and visual inspection shows the DAT lock’s mirror-like surface and no galling.

In comparison to the friction-fit lock, Extreme Components’ DAT lock that had been used by a multinational medical device manufacturer for 4 years of near continuous service, cycling every seven seconds with a 2,300 pound load yielding more than 10 million cycles, was measured to have a surface roughness of only 5.7 micro inches. The data of the surface map displays better uniformity than the friction-fit lock, and visual inspection shows the DAT lock’s mirror-like surface and no galling.

Usually, this measurement was done using far less accurate and time consuming means. However, with the rapid and accurate surface finish analysis data Q-PLUS Lab’s provided, Extreme Components was not only able to effectively compare their DAT locks to traditional friction-fit locks, but visually show customers the value of how their product holds up in real use scenarios.

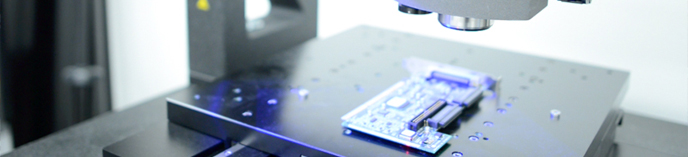

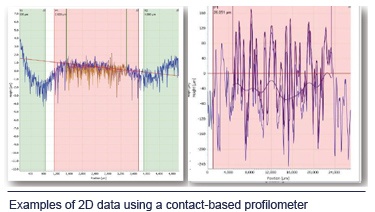

As the name suggests, this type of nano measurement solution will come in contact with the piece to be measured in order to determine its dimensions. The two main types of equipment capable of these measurements are stylus profilometers and the atomic force microscope. Both have been in use for some time and use extremely sensitive styluses to collect the measurement data required.

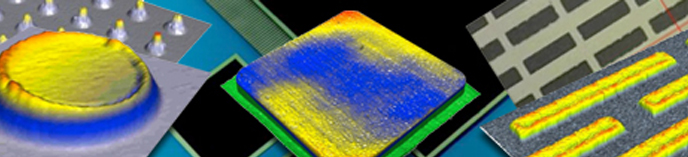

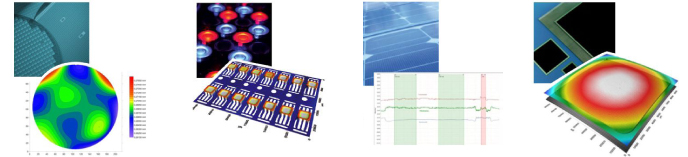

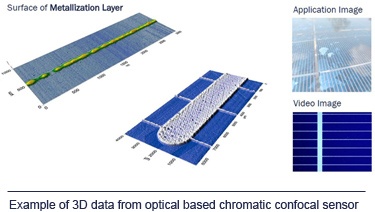

As the name suggests, this type of nano measurement solution will come in contact with the piece to be measured in order to determine its dimensions. The two main types of equipment capable of these measurements are stylus profilometers and the atomic force microscope. Both have been in use for some time and use extremely sensitive styluses to collect the measurement data required. Optical-based nano-measurement technologies are quickly becoming the go-to devices for measurements at the nano level. Since these techniques do not touch the surface of the piece to be measured, there is no risk that small or delicate parts will be damaged or moved during measurement. As an added feature, optical measurements are also done more quickly than traditional contact-based measurements, and typically have an innate ability to obtain 3D measurements in addition to 2D data.

Optical-based nano-measurement technologies are quickly becoming the go-to devices for measurements at the nano level. Since these techniques do not touch the surface of the piece to be measured, there is no risk that small or delicate parts will be damaged or moved during measurement. As an added feature, optical measurements are also done more quickly than traditional contact-based measurements, and typically have an innate ability to obtain 3D measurements in addition to 2D data.