Nanotechnology has matured from science fiction into a burgeoning industry and, now, to a well-accepted component of modern manufacturing. Many people don't realize just how much nanotechnology is involved, not just for high-tech electronics and aerospace, but also for everyday applications such as adhesives, printing, and automobiles.

As measurement capabilities have expanded from the micro to the nano scale, there has been a corresponding improvement in the quality of manufacturing across many types of industries.

3 Advancements in Nano Measurement

With the ability to provide faster, accurate results necessary to monitor quality for products requiring micro manufacturing, developments in nano measurement technologies have introduced new possibilities for manufacturers. Some of the ways that nano measurement has improved the quality of manufacturing include:

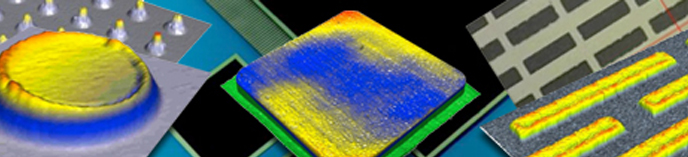

- Electronics - Nano measurement is commonly used for applications such as checking the size, shape, and position of solder bumps on printed circuits and determining the thickness ratios of thin films on microelectromechanical systems (MEMS).

- Solar cells - Analysis and quality control of solar cell manufacturing have also been improved by developments in nano measurement. Nanocrystal solar cells have a very thin coating based on silicon or a similar substrate that has a uniform coating on the surface of the cell. This coating can only be analyzed using nano measurement to confirm uniform thickness.

- Medical diagnostics - Advances in nano measurement are helping researchers develop medical diagnostic tools that are more sensitive and produce consistently reliable results. There are several potential applications for nano measurement in the medical field, including targeted therapy of cardiac diseases, quantitative detection devices for early diagnosis of cancer, and the development of implantable devices for in vivo diagnoses.

Because the field of nano technology is developing at an exponential level, selecting the right nano measurement device (or combination of devices) for a particular surface profilometry, dimensional inspection, or reverse engineering application requires careful consideration to ensure that you receive relevant results in the necessary time frame and within your budget. The experts at Q-PLUS Labs will work closely with you to determine the best solution for you application. Contact us today to schedule a consultation.