Dimensional inspection is employed to measure a broad range of sample types in almost every industry imaginable. This same versatility is required at the nano scale, which is why ongoing effort is put into the development of new measurement technologies.

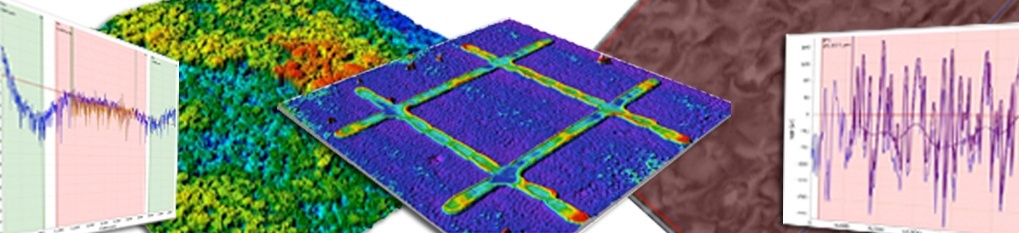

The combination of stylus profilometers, chromatic confocal technology, interferometry, and other types of sensors enables the collection of multiple types of data at the nano level. The ability to use various sensor types, sometimes even for the same sample, makes measuring objects with varying characteristics possible. For example, although using a stylus profilometer to measure an object with a soft surface may not be possible, an optical sensor can solve the problem.

Types of Nano Measurements

Some of the types of measurements that can be obtained at the nano scale include:

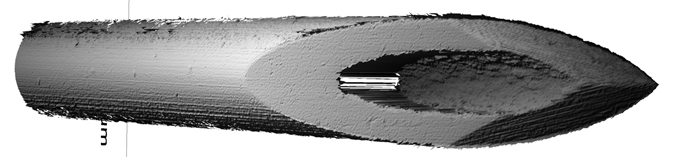

- Form - Micro gears and other small parts require precision shapes and contours. Complex 2D and 3D geometry can be captured at the nano scale with sensors that capture and process point cloud data.

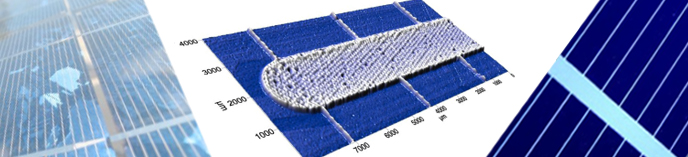

- Roughness - Surface roughness is one of the most common applications for nano measurement. In this case, the type of measurement technology used will depend on the height difference between the highest and lowest points on the surface, whether the material is hard or soft, and the type of results required for the application in 2D or 3D.

- Flatness - The flatness of a pane of glass or man-made sapphire can be measured, regardless of the reflectivity of the surface. When chromatic confocal technology is employed, even the flatness of the opposite side of the glass can also be measured through the translucent material.

- Coplanarity - For a Ball Grid Array (BGA), the top of each solder ball needs to be coplanar with all the others so the mating component seats properly and all connections are made. The geometry of these parts can be measured and verified at the nano scale.

- Roundness - Micro gears and other small parts require precision shapes and contours. The geometry of these parts can be measured and verified at the nano scale.

- Thickness - The thickness of wafers, plastic films, and epoxy films are examples of applications for which nano measurement is often employed. With a chromatic confocal sensor, the thickness of translucent objects, like the glass face of a smartphone, can be determined.

These are not the only types of measurements that can be obtained at the nano scale. The use of multiple types of sensors and the ongoing development of new nano measurement technology are continually expanding the possibilities for manufacturers and researchers.

If you require any of these types of nano measurements, or if you're not sure what approach is needed, the experts at Q-PLUS Labs are here to help. We'll work closely with you through every step of the process to ensure that you get the best results for your application. Contact us anytime if you have questions, or when you're ready to get started.