California State University, Fullerton's SAE (Society of Engineers) Baja is off to the races with a brand new car to dominate the rugged terrain of this year's International competition track in Oregon. Engineering students from CSUF are not only faced with the task of designing and building a "single-seat, all-terrain sporting vehicle that is to be a prototype for a reliable maintainable, ergonomic, and economic production vehicle that serves the recreational user market," but they must do so while also balancing their daily classes, and for some, their jobs as well. Given such a limited amount of time to build a winning vehicle, there is even less room to spend correcting any build errors. Therefore, quality must be built into each vehicle that the SAE Baja Team designs and manufactures, and Q-PLUS Labs provides them the measurement data they need to confidently drive to victory.

Introduction

Every year, a new team assembles for this legacy project where current class seniors pass on their knowledge to upcoming juniors who will in turn pass that knowledge to their lower classmen. This through the process of raising funds to acquire the components to build the vehicle to "exposure with recruiters from leading companies in the mobility industry to help land their first engineering job after graduation." Each car starts from a design concept that has been modified over the past years of competition, however each new competition requires a new car to be built from the ground up. With each competition, the students face the time consuming and challenging process of designing the car, building the chassis, welding, and various test runs.

Every year, a new team assembles for this legacy project where current class seniors pass on their knowledge to upcoming juniors who will in turn pass that knowledge to their lower classmen. This through the process of raising funds to acquire the components to build the vehicle to "exposure with recruiters from leading companies in the mobility industry to help land their first engineering job after graduation." Each car starts from a design concept that has been modified over the past years of competition, however each new competition requires a new car to be built from the ground up. With each competition, the students face the time consuming and challenging process of designing the car, building the chassis, welding, and various test runs.

Our Process

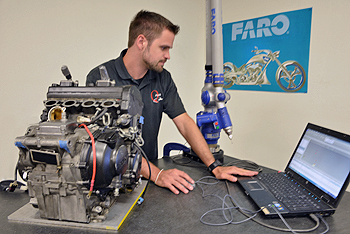

The team's model this year is named after the mascot of California State University, Fullerton – Tuffy the Titan. The overall design for chassis is consistent with the team's past models, however the significant change this year will be the design of the gearbox. Unlike the previous models, this year's model features a smaller gearbox which consequently decreases the length from the input to the output shaft. This will also push the firewall further back and allow more leg room for the driver, which is important when driving on challenging terrain during the competition's four hour endurance course. CSUF's Baja Team approached Q-PLUS Labs to obtain measurement data for their chassis design. Using a FARO arm, Q-PLUS Labs was able to articulate the probe between the areas of the chassis to collect data on the car's body. Accurate measurements will help enable CSUF to confidently move forward with manufacturing the components dependent on these measurements, ensuring that their time is focused on the success of the California State University, Fullerton's SAE Baja team in their race this on May 30th-June 2nd.

The team's model this year is named after the mascot of California State University, Fullerton – Tuffy the Titan. The overall design for chassis is consistent with the team's past models, however the significant change this year will be the design of the gearbox. Unlike the previous models, this year's model features a smaller gearbox which consequently decreases the length from the input to the output shaft. This will also push the firewall further back and allow more leg room for the driver, which is important when driving on challenging terrain during the competition's four hour endurance course. CSUF's Baja Team approached Q-PLUS Labs to obtain measurement data for their chassis design. Using a FARO arm, Q-PLUS Labs was able to articulate the probe between the areas of the chassis to collect data on the car's body. Accurate measurements will help enable CSUF to confidently move forward with manufacturing the components dependent on these measurements, ensuring that their time is focused on the success of the California State University, Fullerton's SAE Baja team in their race this on May 30th-June 2nd.

Before building their vehicle, CSUF's Baja team designed a virtual rendering of it in Solidworks, a 3D CAD design software. Because each piece of the car was hand machined, the team needed accurate measurements of the car’s calipers before proceeding with the build. Calipers are essential to the vehicle’s ability to stop and are one of the critical components of a car’s breaks. The challenging track consisted of rough terrain, making the measurements extremely vital to vehicle’s ability to successfully navigate the race.

Before building their vehicle, CSUF's Baja team designed a virtual rendering of it in Solidworks, a 3D CAD design software. Because each piece of the car was hand machined, the team needed accurate measurements of the car’s calipers before proceeding with the build. Calipers are essential to the vehicle’s ability to stop and are one of the critical components of a car’s breaks. The challenging track consisted of rough terrain, making the measurements extremely vital to vehicle’s ability to successfully navigate the race. ScanArm HD

ScanArm HD

Nam June Paik designed this installation which is composed of televisions paired with Buddhas watching them to depict extended contemplation. As an integral aspect of UCSD's landscape, the university sought to preserve the statues via 3D scan data in case the statues would need to be recreated in detail. For this particular application, Q-PLUS Labs' engineers used white light and laser scanning technology, specifically the

Nam June Paik designed this installation which is composed of televisions paired with Buddhas watching them to depict extended contemplation. As an integral aspect of UCSD's landscape, the university sought to preserve the statues via 3D scan data in case the statues would need to be recreated in detail. For this particular application, Q-PLUS Labs' engineers used white light and laser scanning technology, specifically the

At 378 feet in length and composed of a high speed, semi-planing steel monohull with an aluminum superstructure, the USS Freedom is a unique ship. It is the first-in-class littoral combat ship of its kind and is able to operate in a variety of environments and assignments from dangerous shallow water and near shore missions to minesweeping and humanitarian relief.

At 378 feet in length and composed of a high speed, semi-planing steel monohull with an aluminum superstructure, the USS Freedom is a unique ship. It is the first-in-class littoral combat ship of its kind and is able to operate in a variety of environments and assignments from dangerous shallow water and near shore missions to minesweeping and humanitarian relief.

In order to quickly move the USS Freedom out of port, Q-PLUS Labs was required to acquire the data rapidly and accurately, delivering results which would be used to improve the design of the ship's rear doors. These doors are located near waterline level to allow safe launch and recovery of watercrafts while the ship is in motion. The accuracy of the doors' measurements would allow for improved design to resolve the problems being caused by the shape and position of the currently installed doors.

In order to quickly move the USS Freedom out of port, Q-PLUS Labs was required to acquire the data rapidly and accurately, delivering results which would be used to improve the design of the ship's rear doors. These doors are located near waterline level to allow safe launch and recovery of watercrafts while the ship is in motion. The accuracy of the doors' measurements would allow for improved design to resolve the problems being caused by the shape and position of the currently installed doors.

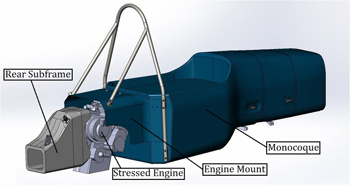

Fullerton's SAE uses a Yamaha R6 Motorcycle engine, a large displacement choice for the 610cc class. The car's design utilizes the R6 engine as a stressed member to connect the drivetrain to the cockpit. This type of engine design requires the chassis to work with the engine as an active structural element of the chassis to transmit forces and torques, rather than using standard anti-vibration mounts to passively contain it. The R6 engine was chosen based off its high power output and ability to be used as a stressed member. In conjunction with suspension design and tire selection, the engine weight works well to keel the tires while heated under the track's conditions.

Fullerton's SAE uses a Yamaha R6 Motorcycle engine, a large displacement choice for the 610cc class. The car's design utilizes the R6 engine as a stressed member to connect the drivetrain to the cockpit. This type of engine design requires the chassis to work with the engine as an active structural element of the chassis to transmit forces and torques, rather than using standard anti-vibration mounts to passively contain it. The R6 engine was chosen based off its high power output and ability to be used as a stressed member. In conjunction with suspension design and tire selection, the engine weight works well to keel the tires while heated under the track's conditions.