The manufacturing industry is experiencing a surge in productivity which is leading to an ever increasing need to verify that the parts being produced meet the specified requirements. When timelines are critical and tolerances are growing ever tighter, it is imperative that the quality process involved in reinforcing the part's requirements consistently adds value to manufacturing. The parts manufactured today have increasingly demanding measurements, and are outgrowing the traditional systems used to measure or reverse engineer them. 3D scanning is a cost-effective solution that brings accuracy and versatility to the evolving landscape of the metrology industry.

4 Key Benefits of 3D Scanning

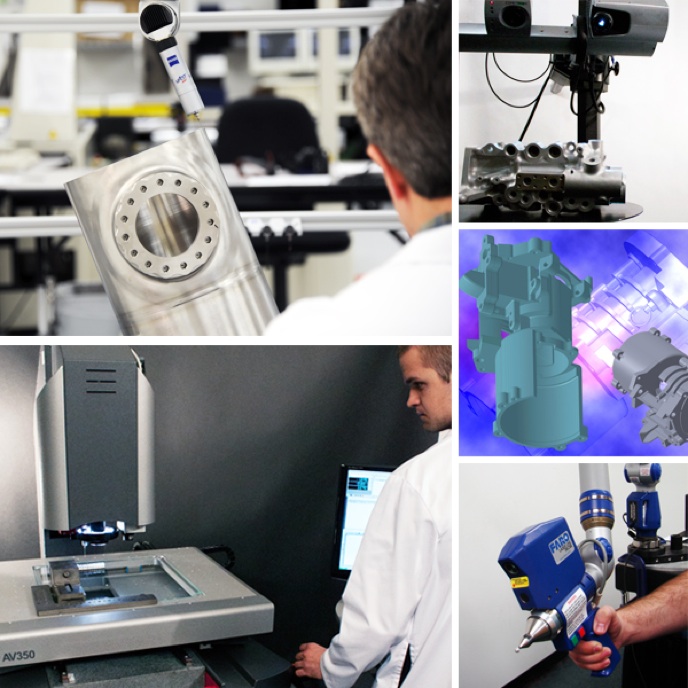

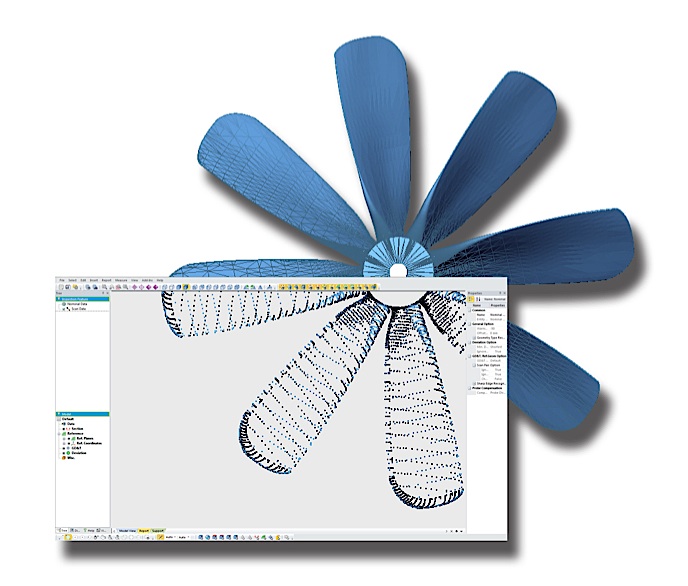

- Coverage - In just a matter of minutes, 3D scanners can collect and measure millions of data points on the surface of an object. This efficiency was not possible before the technology was introduced, which is why it has seen such explosive growth in such a short period of time.

- Speed - Manual measurement takes a long time and is limited by the amount of data that can be practically collected. 3D scanning offers a fast way to automatically collect millions of data points at the speed of light. This reduces the time it would take to traditionally produce CAD models of prototypes or 2D drawings for reverse engineering. By increasing the rate of surface data acquisition, 3D scanning brings unparalleled speed to the inspection process.

- Accuracy - As the technology has improved, the accuracy of 3D scanning has increased over time. Currently, modern scanners provide a high degree of accuracy which is only expected to improve as the ability to collect more and better data points increases.

- Cost - The price of 3D scanning is competitive with other dimensional measurement technologies, especially when you factor in the time savings. Many 3D scanners are also easier to use, which helps to maintain lower training costs.

The type of 3D scanning used will be dependent on the part's surface characteristics such as reflectivity, transparency, and roughness. In some cases, structured light scanning is not an appropriate method because diffraction and reflection can affect the measurements. The best way to decide which type of scanning makes the most sense for your application is to work with a qualified 3D scanning provider that has extensive experience with multiple scanning technologies.

Since 1987, Q-PLUS Labs possesses dimensional metrology expertise and maintains cutting edge 3D scanning techniques. If you need an in-house solution for your application, as a metrology equipment reseller, Q-PLUS Labs works with cutting edge 3D scanner manufacturers to provide customers with objective information on the best fit solution for their application. Contact us today to learn how we can add value to your quality process.

Every year, a new team assembles for this legacy project where current class seniors pass on their knowledge to upcoming juniors who will in turn pass that knowledge to their lower classmen. This through the process of raising funds to acquire the components to build the vehicle to "exposure with recruiters from leading companies in the mobility industry to help land their first engineering job after graduation." Each car starts from a design concept that has been modified over the past years of competition, however each new competition requires a new car to be built from the ground up. With each competition, the students face the time consuming and challenging process of designing the car, building the chassis, welding, and various test runs.

Every year, a new team assembles for this legacy project where current class seniors pass on their knowledge to upcoming juniors who will in turn pass that knowledge to their lower classmen. This through the process of raising funds to acquire the components to build the vehicle to "exposure with recruiters from leading companies in the mobility industry to help land their first engineering job after graduation." Each car starts from a design concept that has been modified over the past years of competition, however each new competition requires a new car to be built from the ground up. With each competition, the students face the time consuming and challenging process of designing the car, building the chassis, welding, and various test runs. The team's model this year is named after the mascot of California State University, Fullerton – Tuffy the Titan. The overall design for chassis is consistent with the team's past models, however the significant change this year will be the design of the gearbox. Unlike the previous models, this year's model features a smaller gearbox which consequently decreases the length from the input to the output shaft. This will also push the firewall further back and allow more leg room for the driver, which is important when driving on challenging terrain during the competition's four hour endurance course. CSUF's Baja Team approached Q-PLUS Labs to obtain measurement data for their chassis design. Using a FARO arm, Q-PLUS Labs was able to articulate the probe between the areas of the chassis to collect data on the car's body. Accurate measurements will help enable CSUF to confidently move forward with manufacturing the components dependent on these measurements, ensuring that their time is focused on the success of the California State University, Fullerton's

The team's model this year is named after the mascot of California State University, Fullerton – Tuffy the Titan. The overall design for chassis is consistent with the team's past models, however the significant change this year will be the design of the gearbox. Unlike the previous models, this year's model features a smaller gearbox which consequently decreases the length from the input to the output shaft. This will also push the firewall further back and allow more leg room for the driver, which is important when driving on challenging terrain during the competition's four hour endurance course. CSUF's Baja Team approached Q-PLUS Labs to obtain measurement data for their chassis design. Using a FARO arm, Q-PLUS Labs was able to articulate the probe between the areas of the chassis to collect data on the car's body. Accurate measurements will help enable CSUF to confidently move forward with manufacturing the components dependent on these measurements, ensuring that their time is focused on the success of the California State University, Fullerton's

Mike was able to take our digital scan and have a replica made using a 3-D printer. Butter Dish 2.0 lives on, and the family tradition remains uninterrupted.

Mike was able to take our digital scan and have a replica made using a 3-D printer. Butter Dish 2.0 lives on, and the family tradition remains uninterrupted.