In order to obtain an engineering degree, you must learn certain concepts and skills in school. However, developing an engineering career means your education continues on the job. One field not typically taught extensively in engineering school is metrology, but for any engineer entering the field of manufacturing, understanding metrology is essential.

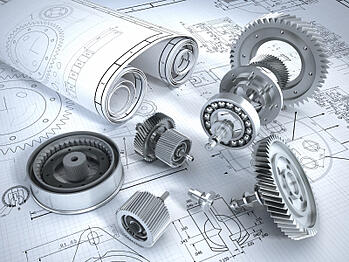

In order to obtain an engineering degree, you must learn certain concepts and skills in school. However, developing an engineering career means your education continues on the job. One field not typically taught extensively in engineering school is metrology, but for any engineer entering the field of manufacturing, understanding metrology is essential. In the simplest terms, metrology is the science of measurement. In practical terms, when it comes to manufacturing, engineers have a vested interest in knowing the fundamentals of geometric dimensioning and tolerancing, commonly referred to as GD&T. Engineering drawings and 3D CAD models use GD&T to communicate engineering dimensions and tolerances to manufacturing and quality staff. If the engineer doesn't know how to effectively communicate in the language of GD&T, the finished product will likely not meet the desired outcome.

Why Understanding Metrology Is Important

The purpose of engineering design is to convey information in a way that makes it as easy as possible for the manufacturing team to create the desired parts and assemblies. A good engineering drawing will consider:- The design intent

- The people and processes involved in manufacturing

- The inspection and verification process

The consequences of not understanding the fundamentals of GD&T can be dire:

- Disruption of manufacturing schedules

- Damaged reputations because of the inability to fulfill requirements

- Inability to meet budgets

Because metrology is so important in the manufacturing industry, there are several benefits for young engineers to learn it sooner rather than later:

- Quality - Good engineering drawings result in parts that match the design intent.

- Budget - Getting a drawing right the first time saves money.

- Time - When dimensions and tolerances are stated clearly and thoroughly, manufacturers do not need to take the time to ask questions or get clarification.

- Customer satisfaction - Producing the correct results in a timely manner keeps customers happy.

So how does a engineer learn more about GD&T if it's not commonly part of the standard curriculum? The American Society of Mechanical Engineers (ASME) offers the Y14.5 - 2009 Dimensioning and Tolerancing specification. This set of guidelines describes the language of GD&T and establishes uniform practices for communicating the requirements on engineering drawings. Additional resources include training programs and traveling seminars.

Q-PLUS Labs offers both training and consulting services to help ensure that your manufacturing process goes as smoothly as possible. Our training programs are designed for small groups across multiple disciplines so that engineers, manufacturing staff, and other key players can learn how to most effectively communicate in the language of GD&T. Contact us today to learn more about how we can help you.

Are you an engineer in the field of manufacturing? Tell us in the comments section how you learned about GD&T.

Optical illusion: parallel lines made from black and white pillows

Optical illusion: parallel lines made from black and white pillows Dimensional inspection is used in a broad range of industries for a wide variety of applications. However, there are some common reasons why this type of measurement is used. Whether the objective is to compare a prototype to a drawing or to ensure that a finished product meets certain standards, the fundamentals of dimensional inspection remain the same. Highly accurate measurements are taken to determine how closely an object matches its originally intended dimensions.

Dimensional inspection is used in a broad range of industries for a wide variety of applications. However, there are some common reasons why this type of measurement is used. Whether the objective is to compare a prototype to a drawing or to ensure that a finished product meets certain standards, the fundamentals of dimensional inspection remain the same. Highly accurate measurements are taken to determine how closely an object matches its originally intended dimensions.

Purchasing dimensional inspection equipment requires making a big decision, and in most cases a significant financial investment. It is important to be certain that the equipment you buy will serve its intended purpose and provide the results you need.

Purchasing dimensional inspection equipment requires making a big decision, and in most cases a significant financial investment. It is important to be certain that the equipment you buy will serve its intended purpose and provide the results you need. The simplest solution is often the best. This old adage applies to almost anything, including dimensional inspection. In a room full of high-tech equipment like

The simplest solution is often the best. This old adage applies to almost anything, including dimensional inspection. In a room full of high-tech equipment like  For some

For some  Dimensional inspection can be performed with a wide variety of methods and equipment, depending on the object being measured. When selecting equipment, remember the cardinal rule of dimensional inspection: The object being measured cannot be altered during the measurement process. This means that some objects cannot be touched because the resulting measurements will be inaccurate.

Dimensional inspection can be performed with a wide variety of methods and equipment, depending on the object being measured. When selecting equipment, remember the cardinal rule of dimensional inspection: The object being measured cannot be altered during the measurement process. This means that some objects cannot be touched because the resulting measurements will be inaccurate. 3D scanning can be used for a broad range of applications. For example, you might want to create a replica of an artifact or inspect a sand casting to a 3D CAD model. However, not all dimensional measurement applications warrant the use of 3D scanning. In some cases, a different or simpler approach might be appropriate.

3D scanning can be used for a broad range of applications. For example, you might want to create a replica of an artifact or inspect a sand casting to a 3D CAD model. However, not all dimensional measurement applications warrant the use of 3D scanning. In some cases, a different or simpler approach might be appropriate. 3D scanning can be used for a broad range of applications, some of which you might not expect. It can be employed in any situation where the size, shape, and surface characteristics of an object are important. Advances in the technology have further broadened the scope of its utility. It is possible to measure geometry with greater accuracy as well as to capture small details that were previously not possible to measure.

3D scanning can be used for a broad range of applications, some of which you might not expect. It can be employed in any situation where the size, shape, and surface characteristics of an object are important. Advances in the technology have further broadened the scope of its utility. It is possible to measure geometry with greater accuracy as well as to capture small details that were previously not possible to measure. Reverse engineering

Reverse engineering