When you think about your daily life the topic of dimensional inspection will likely never come up. In fact, many people could go through their lives not understanding how dimensional inspection works, let alone how it fits into almost every aspect of their daily lives through the products they use. From the coffee cup that you may be holding right now as you read this article to the car you drive (hopefully not while you are reading this article), dimensional inspection was an integral part of the manufacturing process for all of the products you use in your daily life.

What Is Dimensional Inspection?

Simply put, dimensional inspection is the measurement of the distances between different features on a part. If you have a block that is supposed to be one inch long, then dimensional inspection will tell you exactly how long that block actually is. This is a simple case, but think about the intricate measurements required to make sure that each individual part of your car engine will fit together properly in order to move the pistons for you to be able to drive your car.

Even your simple water bottle needs to have very close dimensional measurements in order for the bottle top to screw onto the bottle and provide a tight seal for the water; if the dimensions are not correct then you may have trouble storing the bottle without spilling its contents, or even have an issue trying to fit the lid back onto it once you’ve removed it. This ability of the parts to connect correctly is designed into the dimensions of each part, but dimensional inspection of the individual parts to make sure they meet the design is what ensures the end product will work when it gets to you.

When it is not feasible to measure each dimension on each part, (for instance water bottles would become very expensive), dimensional inspection is used on the tools that make the parts such as injection molding dies that form a water bottle out of molten plastic. If the tool dies are ensured to have the right measurements, then the resulting bottles will be correct; a company can then check a sample product at intervals to make sure that the forming process is working properly as it progresses. So even then dimensional inspection is used on a sample basis.

Dimensional Inspection: 3 Surprising Facts

It should no longer surprise you that dimensional inspection is found throughout the manufacturing processes of almost every product that you use to ensure the safety and integrity of those products, but there are still some facts about dimensional inspection that you might find surprising.

- Tight tolerances: Dimensions are never measured to exactly what the design measurement should be (called the nominal dimension) so each design will have a tolerance on the dimension; basically, a stated amount that the dimension can be different from the nominal dimension. So, if you have a measurement that needs to be at one inch, but can be different from this measurement by one-sixteenth of an inch, your tolerance would be +/- (plus or minus) one sixteenth of an inch. In some industries, such as the space industry that builds satellites or parts for the space station these tolerances can be very tight, such as one ten thousandth of an inch (0.0001”) in order for the parts to work reliably in the space environment. This is for the safety of the astronauts or for the reliability of the satellite since you cannot fix a problem once in orbit.

- Tighter measurements: A general rule of dimensional inspection is that the dimensional measuring equipment should be ten times better than the tolerance being measured. That means if you are measuring something to the nearest inch your measuring equipment needs to be able to measure to one tenth of an inch. For the above example, if you are measuring to one ten thousandth of an inch (0.0001”) your measuring equipment needs to be accurate to one hundred thousandth of an inch (0.00001”). So, dimensional measurement equipment can be extremely accurate.

- Calibration: Equipment for dimensional inspection needs to be checked on a regular basis to make sure that it is still measuring as accurately as it is designed to measure. This verification is done against a very accurate standard part or specimen that has been designed and verified to a certain dimensions and tolerances. By ensuring that the dimensional equipment measures the standard correctly you can be confident that the equipment is functioning properly. Most of these standards are traceable back to the National Institute of Standards and Technology (NIST), which is part of the United States Department of Commerce, but is a non-regulatory agency. NIST is the foremost measurement standards laboratory and is used as the standard for calibrations in most industries.

Dimensional Measurements: In-House or Outsourced

While many companies keep all of the equipment they need to perform all of their dimensional inspections sometimes the equipment is so expensive, and the measurements taken so infrequently, that it makes more sense to have an expert laboratory do the measurements for you. In either case the experts at Q-PLUS are the place to turn for either help on the right equipment to purchase, or the accurate tools to measure your most intricate dimensions and the skilled operators to run that equipment.

Q-PLUS Labs has been a leading dimensional measurement laboratory since 1987; providing one place for precision measurement solutions. As a lab registered to ISO 9001 and accredited to ISO 17025, you can be certain that you will get the right dimensional measurements and calibrations every time.

This year, California State University, Fullerton's Formula SAE is using a Yamaha FZ-07 motorcycle engine which has increased displacement for their new race car design. The new design for the chassis will include a space frame as well as a carbon fiber driver cell. The space frame is created by welding steel tubes together and attaching them to the cockpit and the engine housing, as well as the drive train. Unlike the team's last design which was a stressed engine, this design will be mounted to the inside of the space frame. Weighing 20 to 30 pounds less than the team's original engine, this choice also offers more torque and faster acceleration without creating a heavier car which would give the team an edge against their competition.

This year, California State University, Fullerton's Formula SAE is using a Yamaha FZ-07 motorcycle engine which has increased displacement for their new race car design. The new design for the chassis will include a space frame as well as a carbon fiber driver cell. The space frame is created by welding steel tubes together and attaching them to the cockpit and the engine housing, as well as the drive train. Unlike the team's last design which was a stressed engine, this design will be mounted to the inside of the space frame. Weighing 20 to 30 pounds less than the team's original engine, this choice also offers more torque and faster acceleration without creating a heavier car which would give the team an edge against their competition.

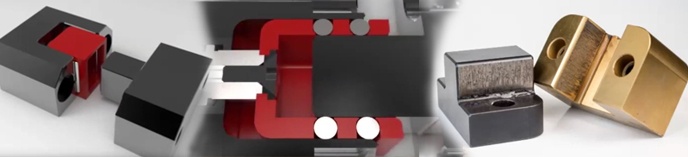

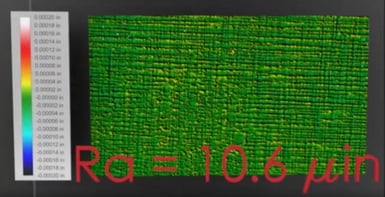

To analyze the exact amount of wear, Q-PLUS Labs performed a surface roughness analysis to confirm the wear on the unused surface of a traditional friction-fit lock versus the wear experienced by Extreme Components LP’s DAT locks after multiple uses. This was accomplished using

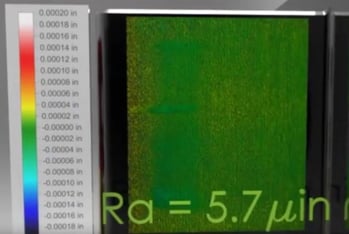

To analyze the exact amount of wear, Q-PLUS Labs performed a surface roughness analysis to confirm the wear on the unused surface of a traditional friction-fit lock versus the wear experienced by Extreme Components LP’s DAT locks after multiple uses. This was accomplished using  In comparison to the friction-fit lock, Extreme Components’ DAT lock that had been used by a multinational medical device manufacturer for 4 years of near continuous service, cycling every seven seconds with a 2,300 pound load yielding more than 10 million cycles, was measured to have a surface roughness of only 5.7 micro inches. The data of the surface map displays better uniformity than the friction-fit lock, and visual inspection shows the DAT lock’s mirror-like surface and no galling.

In comparison to the friction-fit lock, Extreme Components’ DAT lock that had been used by a multinational medical device manufacturer for 4 years of near continuous service, cycling every seven seconds with a 2,300 pound load yielding more than 10 million cycles, was measured to have a surface roughness of only 5.7 micro inches. The data of the surface map displays better uniformity than the friction-fit lock, and visual inspection shows the DAT lock’s mirror-like surface and no galling.

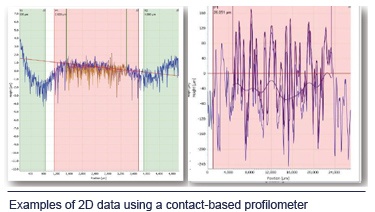

As the name suggests, this type of nano measurement solution will come in contact with the piece to be measured in order to determine its dimensions. The two main types of equipment capable of these measurements are stylus profilometers and the atomic force microscope. Both have been in use for some time and use extremely sensitive styluses to collect the measurement data required.

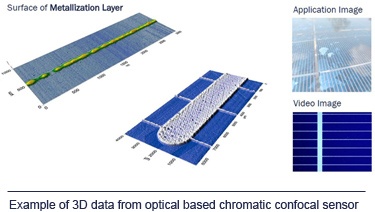

As the name suggests, this type of nano measurement solution will come in contact with the piece to be measured in order to determine its dimensions. The two main types of equipment capable of these measurements are stylus profilometers and the atomic force microscope. Both have been in use for some time and use extremely sensitive styluses to collect the measurement data required. Optical-based nano-measurement technologies are quickly becoming the go-to devices for measurements at the nano level. Since these techniques do not touch the surface of the piece to be measured, there is no risk that small or delicate parts will be damaged or moved during measurement. As an added feature, optical measurements are also done more quickly than traditional contact-based measurements, and typically have an innate ability to obtain 3D measurements in addition to 2D data.

Optical-based nano-measurement technologies are quickly becoming the go-to devices for measurements at the nano level. Since these techniques do not touch the surface of the piece to be measured, there is no risk that small or delicate parts will be damaged or moved during measurement. As an added feature, optical measurements are also done more quickly than traditional contact-based measurements, and typically have an innate ability to obtain 3D measurements in addition to 2D data.

A little background on the rigorous Baja SAE race—it originated in 1976 at the University of South Carolina as a comprehensive engineering competition with the objective for students to function as a team and not only design, build, test, promote, and race a vehicle, but also raise financial support while balancing the demands of their course work. In order to compete as formidable opponent at the 2016 Baja SAE race, the final single-seat, all-terrain sporting vehicle is comprised of parts machined by CSUF’s Baja team.

A little background on the rigorous Baja SAE race—it originated in 1976 at the University of South Carolina as a comprehensive engineering competition with the objective for students to function as a team and not only design, build, test, promote, and race a vehicle, but also raise financial support while balancing the demands of their course work. In order to compete as formidable opponent at the 2016 Baja SAE race, the final single-seat, all-terrain sporting vehicle is comprised of parts machined by CSUF’s Baja team. cle’s ability to successfully navigate the race due to the challenging track. CSUF’s Baja team requested Q-PLUS Labs to 3D scan the cutting brake that provided the team with measurement data from which they can derive the best fit area of the car to mount the brake. Using the

cle’s ability to successfully navigate the race due to the challenging track. CSUF’s Baja team requested Q-PLUS Labs to 3D scan the cutting brake that provided the team with measurement data from which they can derive the best fit area of the car to mount the brake. Using the

Before building their vehicle, CSUF's Baja team designed a virtual rendering of it in Solidworks, a 3D CAD design software. Because each piece of the car was hand machined, the team needed accurate measurements of the car’s calipers before proceeding with the build. Calipers are essential to the vehicle’s ability to stop and are one of the critical components of a car’s breaks. The challenging track consisted of rough terrain, making the measurements extremely vital to vehicle’s ability to successfully navigate the race.

Before building their vehicle, CSUF's Baja team designed a virtual rendering of it in Solidworks, a 3D CAD design software. Because each piece of the car was hand machined, the team needed accurate measurements of the car’s calipers before proceeding with the build. Calipers are essential to the vehicle’s ability to stop and are one of the critical components of a car’s breaks. The challenging track consisted of rough terrain, making the measurements extremely vital to vehicle’s ability to successfully navigate the race. ScanArm HD

ScanArm HD

Nam June Paik designed this installation which is composed of televisions paired with Buddhas watching them to depict extended contemplation. As an integral aspect of UCSD's landscape, the university sought to preserve the statues via 3D scan data in case the statues would need to be recreated in detail. For this particular application, Q-PLUS Labs' engineers used white light and laser scanning technology, specifically the

Nam June Paik designed this installation which is composed of televisions paired with Buddhas watching them to depict extended contemplation. As an integral aspect of UCSD's landscape, the university sought to preserve the statues via 3D scan data in case the statues would need to be recreated in detail. For this particular application, Q-PLUS Labs' engineers used white light and laser scanning technology, specifically the