Dimensional measurement technology may not be a common topic of conversation for the general public, but it is an essential component of many products that we use every day. It is one of the several behind-the-scenes steps in many manufacturing processes and is also often used during product development.

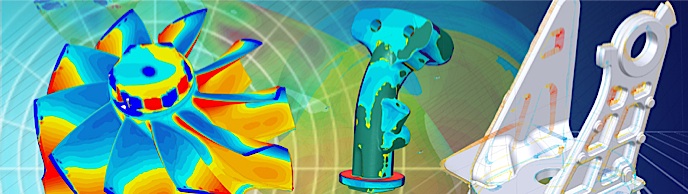

Some ways that dimensional measurement technology can be used include:

- First article inspection - the process of verifying that the initial objects produced on a manufacturing line meet the required specifications

- Reverse engineering - the process of creating a digital replica of an existing object for the purpose of reproduction

- Quality control - verifying that an object's measurements meet the required specifications

Regardless of the reason for dimensional measurement, it is an indispensable process for many industries.

10 Industries that Rely on Dimensional Measurement Technology

Some of the industries that use dimensional measurement technology include:

- Medical - Applications such as prosthetic limbs and implanted medical devices require accurate measurements to ensure the best fit and proper operation.

- Jewelry - Dimensional measurement can be used for replicating an antique ring or creating a precise template for laser cutting earrings.

- Sporting goods - Your carbon fiber golf clubs have a very specific shape that requires dimensional measurement to ensure that the right contours are created during the manufacturing process.

- Dental - Dentists use dimensional measurement to replace lost or broken teeth with implants that exactly match the original.

- Automotive - Dimensional measurement is used throughout the automotive industry to create components that meet industry certification standards.

- Aerospace - Much like the automotive industry, aircraft parts must meet rigorous dimensional specifications.

- Entertainment - Dimensional measurement is employed to create lifelike masks and costumes for special effects, and for realistic digital renderings of people and objects for use in movies and video games.

- Construction - Engineers calculate the strength of certain structures based on their dimensions and shapes. Dimensional measurement is used to ensure that the parts used for construction match the specifications provided by engineers.

- Precision manufacturing - Dimensional measurement can be used in the manufacture of parts such as mirrors and lenses for telescopes that require a high level of accuracy at the sub-micron level.

- Telecommunications - As telecommunications systems become more and more sophisticated, precision-engineered parts are essential. Dimensional inspection ensures that manufactured parts are produced without flaws.

Q-PLUS Labs serves all of these industries and more. We provide first article inspection, reverse engineering, and consulting services to help you set up the right measurement process in-house. In addition to our dimensional measurement services, we also sell several brands of measurement equipment if you decide that you want your own team to perform on-site measurements. Contact us today to schedule your free consultation or to learn more about the services we offer.

Do you use dimensional measurement technology in your industry?