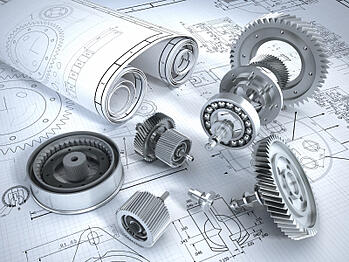

Dimensional inspection is used in a broad range of industries for a wide variety of applications. However, there are some common reasons why this type of measurement is used. Whether the objective is to compare a prototype to a drawing or to ensure that a finished product meets certain standards, the fundamentals of dimensional inspection remain the same. Highly accurate measurements are taken to determine how closely an object matches its originally intended dimensions.

Dimensional inspection is used in a broad range of industries for a wide variety of applications. However, there are some common reasons why this type of measurement is used. Whether the objective is to compare a prototype to a drawing or to ensure that a finished product meets certain standards, the fundamentals of dimensional inspection remain the same. Highly accurate measurements are taken to determine how closely an object matches its originally intended dimensions.

In general, if dimensional measurement is required, the results must be both accurate and precise. Although multiple techniques and countless applications exist, there are four main categories of dimensional inspection.

Four Common Dimensional Inspection Applications

- First article inspection. Implementing a manufacturing process requires extreme attention to detail, especially if the process is new or if the equipment has been specially designed. First article inspection is required to ensure that the equipment was properly installed and calibrated, and to verify the manufacturing process. Dimensional measurement is used to compare the first objects from the manufacturing line to 3-D CAD models or other specifications.

- Quality control. When objects coming off a manufacturing line must meet certain quality standards, measurement equipment is used to confirm that the dimensions fall within the required tolerance levels. In some cases, when the tolerance levels are more rigorous, each object is measured automatically. In other cases, batches might be spot-checked for quality.

- Regulatory compliance. In industries for which regulatory compliance is necessary, dimensional measurement ensures that the required specifications are met. Regulatory bodies such as the FDA or FAA often have requirements regarding the dimensions of certain components.

- High-precision engineering. When creating a larger assembly from smaller parts, high precision is often required. If a minor flaw or inconsistency can impact an entire process, ensuring that such imperfections do not exist is critical.

Employing dimensional measurement in these scenarios offers many benefits, including reduced liability, improved quality, and lower costs.

If you need dimensional inspection services for your business, contact the professionals at Q-PLUS Labs. We provide outsourced measurement services for a range of industries including manufacturing, aerospace, medical, and more. Schedule a consultation today to learn more about how we can help you with your dimensional measurement needs.

How does your company use dimensional inspection?

Purchasing dimensional inspection equipment requires making a big decision, and in most cases a significant financial investment. It is important to be certain that the equipment you buy will serve its intended purpose and provide the results you need.

Purchasing dimensional inspection equipment requires making a big decision, and in most cases a significant financial investment. It is important to be certain that the equipment you buy will serve its intended purpose and provide the results you need. The simplest solution is often the best. This old adage applies to almost anything, including dimensional inspection. In a room full of high-tech equipment like

The simplest solution is often the best. This old adage applies to almost anything, including dimensional inspection. In a room full of high-tech equipment like

For some

For some  Dimensional inspection can be performed with a wide variety of methods and equipment, depending on the object being measured. When selecting equipment, remember the cardinal rule of dimensional inspection: The object being measured cannot be altered during the measurement process. This means that some objects cannot be touched because the resulting measurements will be inaccurate.

Dimensional inspection can be performed with a wide variety of methods and equipment, depending on the object being measured. When selecting equipment, remember the cardinal rule of dimensional inspection: The object being measured cannot be altered during the measurement process. This means that some objects cannot be touched because the resulting measurements will be inaccurate. 3D scanning can be used for a broad range of applications. For example, you might want to create a replica of an artifact or inspect a sand casting to a 3D CAD model. However, not all dimensional measurement applications warrant the use of 3D scanning. In some cases, a different or simpler approach might be appropriate.

3D scanning can be used for a broad range of applications. For example, you might want to create a replica of an artifact or inspect a sand casting to a 3D CAD model. However, not all dimensional measurement applications warrant the use of 3D scanning. In some cases, a different or simpler approach might be appropriate. 3D scanning can be used for a broad range of applications, some of which you might not expect. It can be employed in any situation where the size, shape, and surface characteristics of an object are important. Advances in the technology have further broadened the scope of its utility. It is possible to measure geometry with greater accuracy as well as to capture small details that were previously not possible to measure.

3D scanning can be used for a broad range of applications, some of which you might not expect. It can be employed in any situation where the size, shape, and surface characteristics of an object are important. Advances in the technology have further broadened the scope of its utility. It is possible to measure geometry with greater accuracy as well as to capture small details that were previously not possible to measure. 3D scanners are increasingly used for

3D scanners are increasingly used for  Reverse engineering allows you to obtain the exact dimensions of an object so you can replicate it. Specialized laboratories have various types of equipment to measure almost any type of object, no matter how large or small, or detailed or precise. The measurements are then delivered in a format that will allow you to produce a copy. You might need to reverse engineer a custom part, an object that does not have original design plans, or a unique antique.

Reverse engineering allows you to obtain the exact dimensions of an object so you can replicate it. Specialized laboratories have various types of equipment to measure almost any type of object, no matter how large or small, or detailed or precise. The measurements are then delivered in a format that will allow you to produce a copy. You might need to reverse engineer a custom part, an object that does not have original design plans, or a unique antique.  Reverse engineering

Reverse engineering