Bluing and scribing of castings (also known as casting layout) is a tried-and-true method for dimensional inspection of a metal part made typically by sand casting or permanent mold. By placing the dimensions from a drawing on to the actual part, you can determine whether it meets the specifications. Although this method has been used for decades, new technologies have effectively superseded the need for it in most cases.

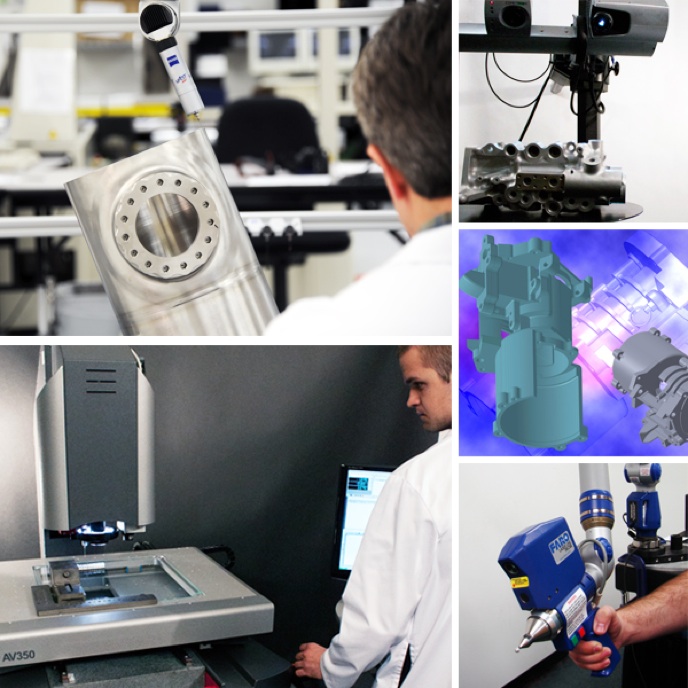

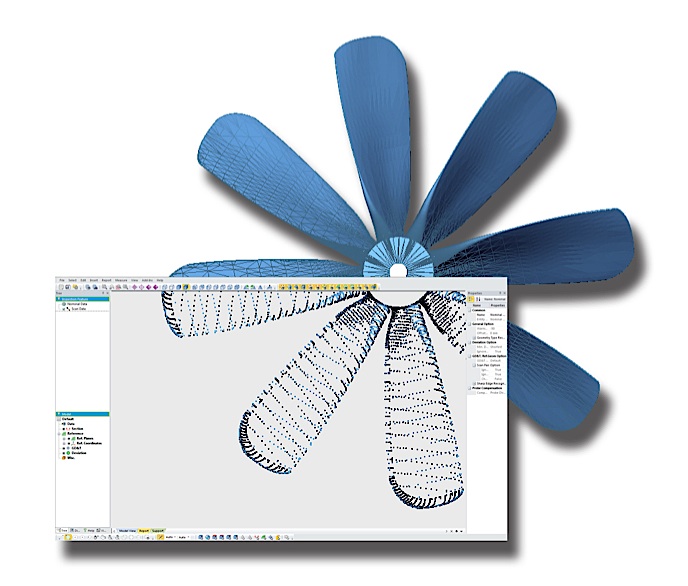

For example, 3D scanning can be used to superimpose points on a 3D model with a corresponding profile and dimensional analysis to show deviations from the drawing as well as quantify them. Of course, like any technology, even the most advanced systems come with pros and cons. With new options that are faster and more accurate, it makes sense to ask why we are still bluing and scribing castings.

Advantages of Bluing and Scribing Castings

Even though it is an older technology, bluing and scribing continues to offer several advantages:- Proof of inspection - Unlike a digital scan that leaves no trace, bluing and scribing creates an obvious indicator that the part has been inspected. This can be useful during quality control procedures to ensure that parts have been inspected.

- Visualization - Bluing and scribing allows you to see whether a part matches the drawing or not, sometimes quickly after the procedure has been completed. And if it doesn't match, it's easy to see what direction the error is in.

- Tradition - Bluing and scribing is a traditional dimensional inspection method that many seasoned professionals are comfortable with. Changing approaches can be intimidating, but adding new technologies to traditional ones can generate even better results.

Disadvantages of Bluing and Scribing Castings

Advances in technology have illuminated some inherent disadvantages to bluing and scribing that may not have been as noticeable in the past:

- Speed - Despite its advantages, bluing and scribing takes time, more than with alternative methods such as CMM and 3D scanning. For applications such as first article inspection, when time is of the essence, more modern approaches may be more appropriate.

- Cost - Bluing and scribing can be expensive when compared with other technologies, especially when you factor in the time is takes to do it.

- Accuracy - 3D scanners and CMM technology provide more accurate results than bluing and scribing castings, and the subsequent dynamic graphical results are easier to evaluate.

- Record keeping - With a blue and scribe layout, when the part is returned to the customer along with an inspection report, so are the visualization results: They are on the casting itself. With 3D scanning, a virtual part is retained on file for proper record keeping. This is particularly useful when the customer has questions about the results.

If you are looking for a provider that can offer both traditional and cutting-edge dimensional inspection services, get in touch with Q-PLUS Labs today. We'll help you evaluate your needs for each specific application and recommend a balanced approach that meets the necessary requirements in the most cost-effective manner.

Even though we now have more advanced technology, what do you think about bluing and scribing castings?

Mike was able to take our digital scan and have a replica made using a 3-D printer. Butter Dish 2.0 lives on, and the family tradition remains uninterrupted.

Mike was able to take our digital scan and have a replica made using a 3-D printer. Butter Dish 2.0 lives on, and the family tradition remains uninterrupted. In order to obtain an engineering degree, you must learn certain concepts and skills in school. However, developing an engineering career means your education continues on the job. One field not typically taught extensively in engineering school is metrology, but for any engineer entering the field of manufacturing, understanding metrology is essential.

In order to obtain an engineering degree, you must learn certain concepts and skills in school. However, developing an engineering career means your education continues on the job. One field not typically taught extensively in engineering school is metrology, but for any engineer entering the field of manufacturing, understanding metrology is essential.

Optical illusion: parallel lines made from black and white pillows

Optical illusion: parallel lines made from black and white pillows